Botres Global can be proud of its excellent results in terms of biogas yields and rapid methane generation. Our anaerobic digestion process is stable, and our technology is not limited to one type of substrate, on the contrary, it is very flexible.

For many years we achieve very high efficiency through the separation of hydrolysis and methane fermentation. In hydrolysis phase, large compounds are cracked down by bacterial enzymatic activity, causing partial acidification and hydrolysis. After hydrolysis, methane fermentation is more efficient and faster; the pH remains at 7.5 to 8.5, thanks to optimal equilibrium of volatile fatty acids (VFA), amino acids, NH4+ and rapid conversion of VFA and Hydrogen into biogas.

The advantages do not end there. A potentially low pH (e.g. food waste) of the input substrate has no negative effect on the process itself. There is no leakage of microorganisms, no inhibition due to high N and S content.

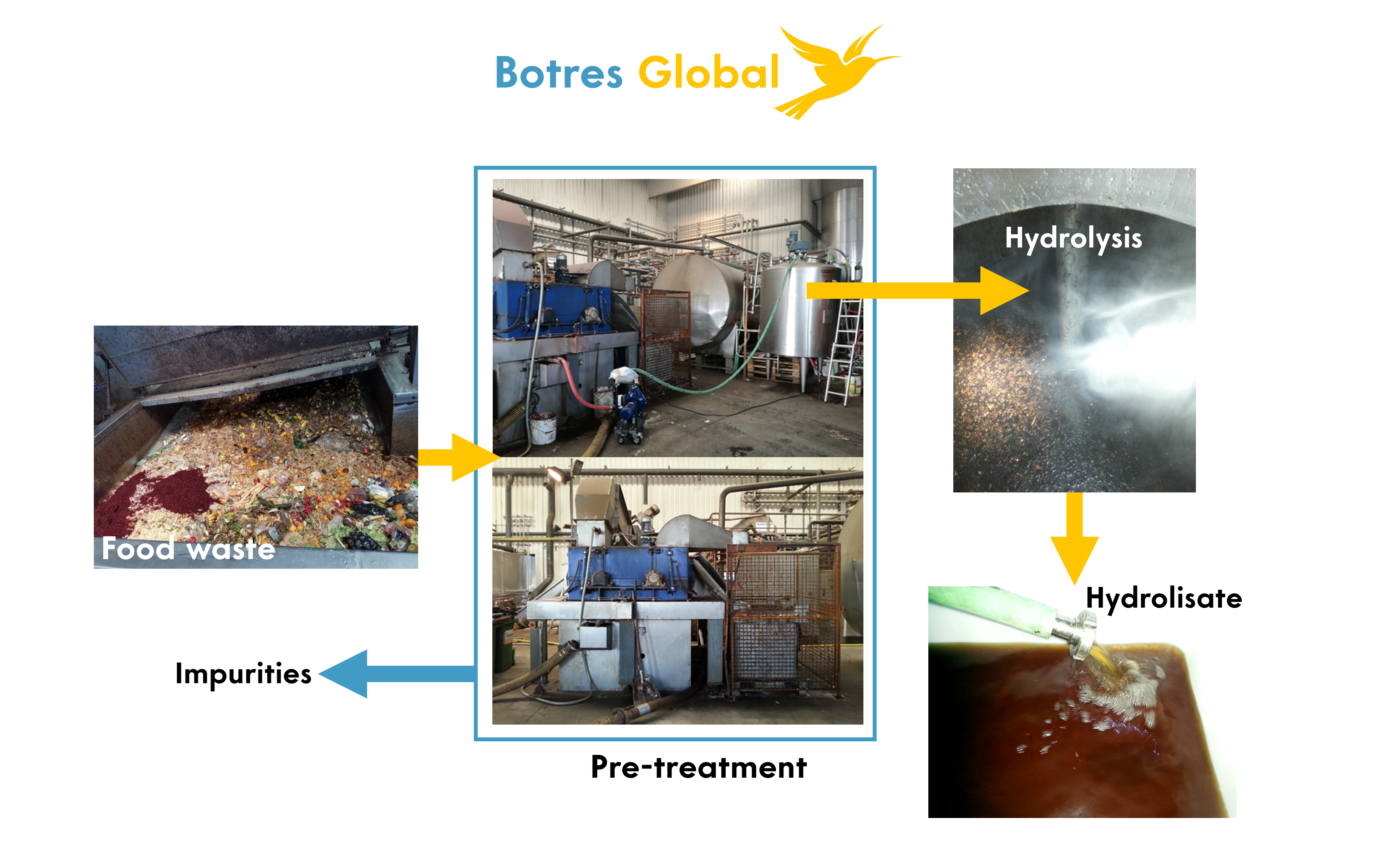

Recently, our CEO and CTO of our company – Dr. Stefan Kromus and Dr. Markus Grasmug coordinated scientific research on the topic: “Cultivation of heterotrophic algae on enzymatically hydrolyzed municipal food waste”. A side effect of participation in the project is the optimisation of pretreatment and full-scale hydrolysis.

In this study, the cultivation of the heterotrophic algae Chlorella sorokiniana on enzymatically hydrolysed food waste was investigated. Nitrogen that is not fully converted can later contaminate water and soil when subsequently stored. The study showed that hydrolysed food waste is not only an excellent substrate for anaerobic digestion, but also for the production of Chlorella sorokiniana biomass. This is both important and useful because the left nitrogen can be converted into valuable proteins. This makes them an excellent source for the production of high-quality animal feed. As a result, we went into more detail regarding hydrolysis of food waste by enzymes prior to fermentation. In full scale biogas plants, we don’t use external enzymes but enzymatic/hydrolytic activity of anaerobic bacteria. However, the R&D project was meant to discover results in a pilot plant to give input for the optimization and automation of hydrolysis in full scale. Very important findings comprise the glucose and acetic acid availability in the hydrolysate. Especially glucose concentration in hydrolysate could be increased 5-6 times compared to the initial food waste slurry. But also, pH drop and increase of acetic acid concentration was observed.

The results show clearly that the hydrolysis step is considerably supporting and enhancing biogas production. The main methane fermenter can work much more efficient if the bacteria can “focus” on pre-destructed molecules, like glucose (from starch) and volatile fatty acids (from fat). Additionally, the availability of free amino acids out of proteins is beneficial for a stable and rapid conversion rate. The operation of the methane fermentation step with a high bacterial density is supporting the interspecies hydrogen transfer and therefore increasing the hydrogen conversion.

This holds not only for food waste, but also for other substrates which have a high nitrogen content (e.g., chicken litter). The hydrogen concentration in the fermenter can be a very important indicator for the stability of the system and the degree of inhibition by ammonia (undissociated ammonia inhibition). A rapid conversion of free hydrogen into methane leads to a lower hydrogen concentration and therefore to a higher tolerable ammonia concentration in the fermenter. This is one “ingredient” why Botres Global has a 50% higher tolerance for nitrogen in the substrate than other suppliers. However, there are many more aspects important – e.g., temperature, substrate pre-treatment, automation system, etc.

Thus, hydrolysis has an important impact on optimal biogas production. Botres Global applies hydrolysis in full scale for more than 10 years.